Chapter 12. Explosion and Fire Analysis

12.1. Explosion and Fire Analysis

12.2. Methodology

12.3. Screening Techniques

12.4. Release Flow Rates

12.5. Identifying Fire or Explosion Hazard

12.6. Missile Generation

12.7. Fire and Explosion Characteristics

12.8. Boiling Liquid Expanding Vapor Explosion (BLEVE)

12.9. BLEVE

12.10. Equations for BLEVE Fireball

12.11. Pool Fires

12.12. Unconfined Vapor Cloud Explosion (UVCE)

12.13. Cloud Model for UVCE

12.14. Effect of Fires and Explosions on Personnel and the Plant

12.15. Effect of Heat Flux on Human Health and the Plant

12.16. Effect of Explosive Pressure on Human Health

12.17. Estimating Energy of an Explosion from Damage Assessment

12.18. Estimating Energy of an Explosion from Damage Assessment(contd.)

12.19. Estimating Energy of an Explosion from Damage Assessment(contd.)

12.20. Estimating Energy of an Explosion from Damage Assessment(contd.)

12.21. Estimating Energy of an Explosion from Damage Assessment(contd.)

12.1. Explosion and Fire Analysis

Identify potential effects of chemical plant accidents on plant personnel and inhabitants of the surrounding area

Many chemicals used in chemical plants present fire and explosion hazards. Explosions and fires have been the most significant safety problems in chemical plants in terms of worker safety and equipment losses.

Most low and medium molecular weight organic compounds are flammable and/or explosive when mixed with air under certain conditions. A major part of plant design is avoiding the possibility of flammable mixtures except under desired and controlled conditions.

For a fire or explosion to occur, the fuel and oxidizer must be in a concentration range between the lower and upper flammability limits, and there must be an ignition source.

The objective of explosion and fire analysis is to identify the potential effects of chemical plant accidents on plant personnel and the inhabitants of the area surrounding the plant.

12.2. Methodology

The first step in performing an explosion and fire analysis is to identify the fire or explosion scenarios to be analyzed. This slide shows what is to be included in this analysis. Missile generation refers to pieces of equipment that are blasted into other process vessels from an explosion.

12.3. Screening Techniques

Use hazard identification techniques to define the fire or explosion events to be analyzed

Hazard identification techniques are used for fire or explosion scenarios to postulate chemical release flow rates and identify the type of fire or explosion hazards. These include failure mode and effects analysis, (FEMA), hazard and operability studies (HAZOP), and fault tree analysis (FTA), for example.

12.4. Release Flow Rates

Chemical release rates can be determined by applying the mechanical energy balance

Analysis Considers:

For postulated pipe ruptures, failed pumps, valves, and flanges, the chemical release flow rate can range from very high to very low. Standard engineering calculations using the mechanical energy balance are used to estimate these flow rates. These calculations require estimating pressures and cross-sectional areas for ruptures which lend uncertainty to the evaluations.

12.5. Identifying Fire or Explosion Hazard

The release rate and phase of the chemical release determines the type of fire or explosion hazard. Rapid release of a liquid stored above its boiling point can result in a boiling liquid, expanding vapor explosion (BLEVE). If a gas leak occurs resulting in a slow build up of flammable gas in the atmosphere, a cloud may form. If enough of the flammable gas accumulates and ignition results within the cloud, an unconfined vapor cloud explosion (UVCE) occurs.

12.6. Missile Generation

Catastrophic failures of equipment can result in equipment fragments being propelled to other areas of the plant

In conducting this analysis, one must also identify equipment that can be propelled to other areas of the plant during a catastrophic failure. These can cause serious damage and additional explosions and fires.

12.7. Fire and Explosion Characteristics

Fires and explosions fall into three categories as shown on this slide. The next slides will describe calculations for estimating the radius, duration, and heat release of these explosions and fires. This information is needed to assess damage to persons and process units.

12.8. Boiling Liquid Expanding Vapor Explosion (BLEVE)

A boiling liquid expanding vapor explosion can result from a rapid release and vaporization of a volatile chemical following a catastrophic rupture of a tank. This chemical has a boiling point below the ambient temperature.

12.9. BLEVE

This explosion produces intense thermal radiation in the form of a fireball. Equations are available for the calculation of the radius, duration, radiant energy, radiant fraction of the fireball as well as the radiant heat flux away from the fireball.

12.10. Equations for BLEVE Fireball

Radius of fireball, r, meters: m – mass of release, kg.

r = 2.665 m 0.327

Duration of fireball (sec)

t = 1.089 m 0.327

Radiant energy released (joules)

Qr = Hc m n

where n = 0.27 P00.32 and P0 is the storage pressure (Mpa)

qr - radiant heat flux where qr = Qr / Ar where Ar - area of hemisphere

These are the equations that are used to estimate the radius and duration of the fireball and the radiant energy release from Greenberg and Cramer, p. 198-199.

12.11. Pool Fires

Pool fires may result from spills of liquid chemicals for which the boiling point is less than ambient temperature. Greenberg and Cramer provide equations for estimating the radius of a pool fire as a function of density and mass or mass flow rate of the release. Also, equations are given for the burning rate, flame height and radiant heat release for a pool fire.

12.12. Unconfined Vapor Cloud Explosion (UVCE)

Continuous release of a combustible gas into the atmosphere

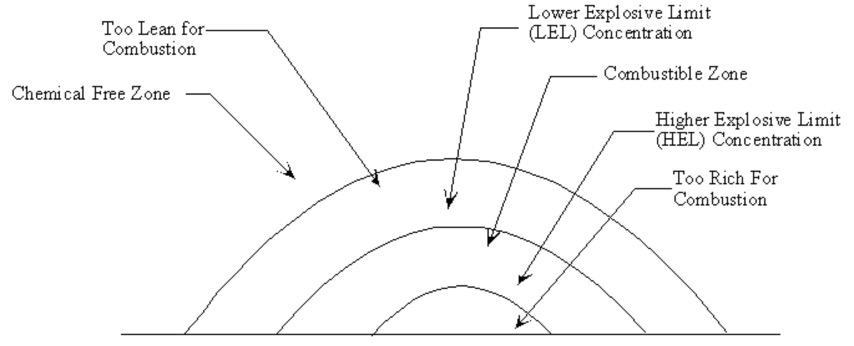

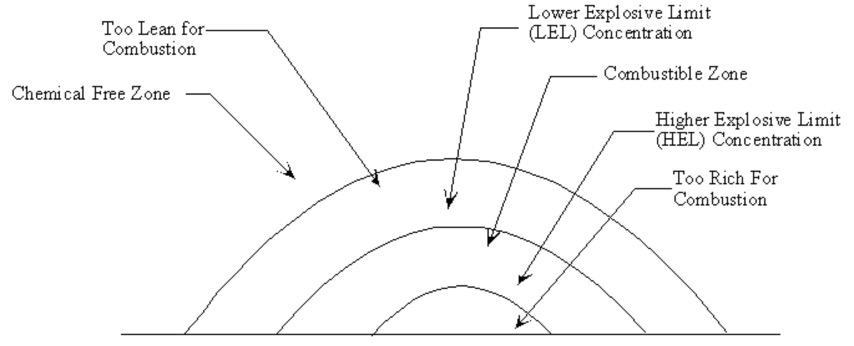

LEL - Lower explosive limit

HEL- The upper or higher explosive limit for which combustion is possible

An explosion is characterized as an UVCE, an unconfined vapor cloud explosion if there is a continuous release of a combustible gas into the atmosphere which results in the formation of a cloud. If enough of the flammable gas accumulates and ignition results within the cloud, an unconfined vapor cloud explosion occurs if an ignition source is present.

For an UVCE to occur the gas must be a combustible mixture. The concentration of fuel and air must be between the lower and upper explosive limits, LEL and HEL. High wind may disperse the gas which would limit the gas concentrations to below the lower explosive limit, LEL.

HEL is the highest concentration for which combustion is possible

12.13. Cloud Model for UVCE

This diagram illustrates the range of compositions in a vapor cloud from the release of a combustible gas. In UVCE analysis, the concentration is integrated over the volume contained within the ellipsoid surfaces to obtain the detonable mass. Greenberg and Cramer, p. 202-207, provide equations to evaluate the concentration ranges shown on this diagram as a function of the gas release rate.

12.14. Effect of Fires and Explosions on Personnel and the Plant

High heat fluxes resulting from chemical fires can cause injury to plant personnel, the public, and can damage the plant

High heat fluxes from chemical fires can cause injury to plant personnel, the public, and can damage the plant. The effect of explosive pressures and heat flux on human health is summarized in tables on the next two slides.

12.15. Effect of Heat Flux on Human Health and the Plant

Heat Flux (Kw/m2) Effect

1.75 Pain threshold reached after 1 minute

2 PVC insulated cables damaged

5 Pain threshold reached after 15 seconds

6.4 Pain threshold reached after 8 seconds, Second degree burns after 20 seconds

12.5 Wood ignites on prolonged exposure in presence of flame

15 Limit for class 2 building materials

16 Severe burns after 5 seconds

25 Wood ignites on prolonged exposure

30 Limit for class 1 building materials

The effect of heat flux on human health and the plant is shown in this table. Notice that 1.75 kilowatts per square meter represents the pain threshold reached after 1 minute.

12.16 Effect of Explosive Pressure on Human Health

Pressure (psi) Effect

5 Eardrum rupture threshold

15 50% probability of eardrum rupture

30-40 Lung damage threshold

80+ Severe lung damage

100-200 Lethality threshold

130-180 50% probability of lethality

200-250 Nearly 100% probability of lethality

The effect of explosive pressure on human health is shown in this chart. It shows that it only takes 5 psi to rupture the eardrum.

12.17. Estimating Energy of an Explosion from Damage Assessment

Overpressure from 1.0 kg of TNT as a function of distance from an explosion is given by:

P (psi) = 1737/D2 + 1.875/D – 0.01156

(D1/D2) = (E1/E2)1/3

D is the range in ft from 3 to 400 ft

Over the years, investigators have correlated the effect of damage from plant explosions with the blast overpressure. The overpressure, in turn, depends on the initial energy of the explosion and the distance from its center. The correlation given in the slide is used to predict the overpressure as a function of distance from the explosion from 1.0 kg of TNT. Also, the distance for equal overpressures scales as the 1/3 power of the energy of the explosion. In the next slide this information will be used to estimate the energy of an explosion from the damage that occurred.

12.18. Estimating Energy of an Explosion from Damage Assessment(contd.)

Damage correlations: psi over pressure (OP)

Knock down people 1 psi OP

Rupture eardrums 5 psi OP

Lung damage 15 psi

Fatality threshold 35 psi OP

50% fatalities 50 psi OP

99% fatalities 65 psi OP

Break wood siding 0.5-1 psi OP

Break cinder block walls 2-3 psi OP

Break telephone poles 5 psi OP

This slide provides additional information on the effect of explosive pressure on human health and plant buildings. This information will be used to estimate the energy from an explosion as described on the next slide.

12.19. Estimating Energy of an Explosion from Damage Assessment(contd.)

Following a major explosion at a chemical plant, the following damage conditions were found. Windows shattered in office building 600 feet away from the center of blast. Wooden utility poles knocked down up to 225 feet away. Within 50 feet of center, there was total destruction of plant. Use the overpressure correlation to evaluate the total energy of the blast in terms of pounds of TNT and BTUs. Compare your results with the calculations given on the next slide.

12.20. Estimating Energy of an Explosion from Damage Assessment(contd.)

The computational procedure is given on this slide. First, select one of the damage criteria to get a distance/overpressure data point. The best choice to use is the utility pole breakage. Then solve the equation for D with P set at 5 psi to calculate the distance that corresponds to this overpressure for 1.0 kg TNT explosion. The scaling formula is used to calculate the energy of the explosion using the conversion factor, 1.0 lb of TNT corresponds to 1983 Btu.

12.21. Estimating Energy of an Explosion from Damage Assessment(contd.)

Select the overpressure of 5.0 psi for breakage of wooden utility poles to determine the distance from the explosion for 1.0 kg TNT.

P = 1737/D2 + 1.875/D - 0.01156

Solving: D = 18.8 ft

Wooden utility poles were broken 225 ft from the explosion. The scaling formula calculates the energy of the explosion in kg TNT as:

(E2/E1)1/3 = (D2/D1)

(E2/1.0) = (225/18.8)3

E2 = 1714 kg TNT = (1714 kg)(2.2 lb/kg) = 3770 lb TNT

E2 = (3770 lb TNT) (1983 Btu/lb TNT) = 7,480,000 Btu

Using an overpressure of 5.0 psi for breakage of wooden utility poles, the distance from the explosion for 1.0 kg TNT is obtained by solving the equation for D, and D = 18.8 ft. Wooden utility poles were broken 225 ft from the explosion, and the scaling formula calculates the energy of the explosion in kg TNT to be 7,480,000 Btu, as shown in the calculations.