Chapter 1. Introduction

1.1. Introduction

1.2. Elements of Risk Management

1.3. Risk and Perception

1.4. Risk and Perception(contd.)

1.5. General Observations by Society

1.6. Safety Engineering

1.7. Life of a Plant

1.1 Introduction

Starting Point

Elements of a Risk Management Program

Perceptions about Risk

Public

Engineer

Perspective of the Life of a Plant

A starting point is provided in this section for terms, ideas and basic elements of a risk management program that are used throughout the course. This include giving the elements of a risk management program and remembering that the public and the engineer have different perspectives about risk. These ideas are viewed from the perspective of the life of a plant.

1.2 Elements of Risk Management

Hazard Identification and Assessment

Risk Mitigation

Operator and Emergency Response Training

Audits

Emergency Response Planning and Procedures

Incident and Accident Investigation

The basic premise behind risk management is minimizing risk by identifying areas of potential risks and controlling them. This figure lists the various elements of a risk management program. This short course will describe methods for these elements. Remember that the best that can be done is to minimize risk, control existing ones and not introduce new ones. There is no such thing as zero risk.

1.3 Risk and Perception

Public

Subjective

Qualitative

Irrational

Intuitive

Misperception

Expert

Objective

Quantitative

Rational

Logical

Reality

This slide provides a comparison between the way the public perceives risks versus the viewpoint of the expert. For instance, the public is very subjective while the technical expert is objective. The public often behaves irrationally as contrasted to the rational thoughts and behaviors of the expert. In addition, the public tends to be subjective, qualitative, irrational, intuitive and often displays misperception while the expert is trying to be objective, quantitative, rational, logical and is realistic. Overall, the general public has been known to use too much emotion and not enough rationale when assessing risks and their consequences.

1.4 Risk and Perception

Risk

Probability x Consequences

Risk Perceptions

Public versus Expert

Before we begin our discussion of risk management, it is important to cover the basics. First, let us define what is meant by the word, “Risk”. In industry, this term implies the product of a probability of an unwanted event occurring times the consequences that would ensue if the event did, in fact, occur. Different groups often perceive risks in very different ways. For instance, there is a sharp contrast in the way technical experts view risks versus the viewpoints of the general public.

1.5 General Observations by Society

Acceptable Risks

Known

Old

Gradual

Usual

Natural

Voluntary

Controllable by Individual

Necessary

Profitable for Individual

Unacceptable Risks

Unknown

New

Sudden

Unusual

Manmade

Involuntary

Uncontrollable by Individual

Luxury

Not Profitable for Individual

This list addresses the characteristics of risks that the general public find acceptable and not acceptable. Greenberg and Cramer use an example of cigarettes to explain why the “known” risk is more acceptable than the “unknown” risk.

For instance, people are less likely to overreact when they breathe cigarette smoke than they are if they smell a strange odor coming from a chemical plant even though the gas from the plant may not be as hazardous.

Another example is used to clarify the difference between “natural” vs. “manmade” risks. The general public seems to accept more readily risks caused by nature like flooding caused by hurricanes than they are to accept infrequent flooding from a broken water main.

1.6 Safety Engineering

Inherent Safety: Potential Dangers have been removed rather than designed for

Extrinsic Safety: Safety is built in by adding controls, alarms, interlocks, equipment procedures, & other mechanisms

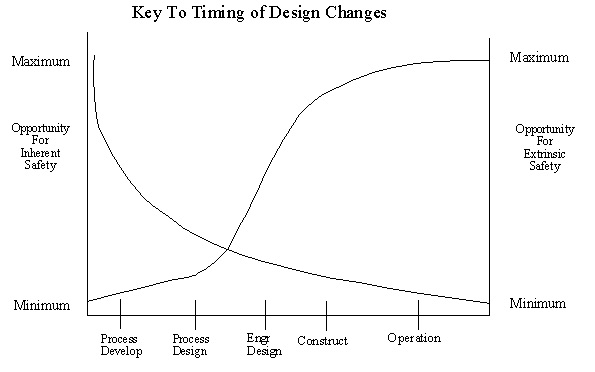

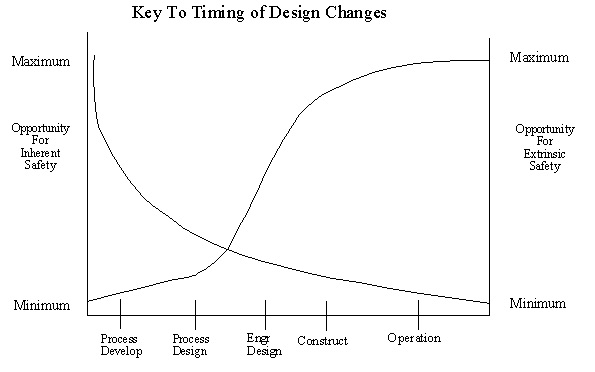

Safety should always be considered at the preliminary stage of any project. In doing this, the costs required to implement it will be reduced. In addition, the project will have a greater probability of being inherently safe because all potential dangers will be removed instead of taken into account in the design.

A project may be considered extrinsically safe if safety is built in by adding controls, alarms, interlocks, equipment procedures, and other mechanisms.

1.7. Life of Plant

This graph illustrates how the life of a plant is divided into five stages: process development, process design, engineering design, construction, and operation. As the process moves from development, design, construction and operation, the opportunity for inherent safety disappears, and there are only opportunities to incorporate extrinsic safety methods which are inherently more expensive.