Chapter 3. Screening Analysis Techniques

3.1. Screening Analysis Techniques

3.2. Dow Fire and Explosion Index

3.3. Dow Fire and Explosion Index(contd.)

3.4. Dow Fire and Explosion Index(contd.)

3.5. Loss Control Credit Factors

3.6. Unit Analysis Summary

3.7. Mond Fire, Explosion and Toxicity Index

3.8. Recommendations

3.9. Recommendations(contd.)

3.10. Mond Procedure

3.11. Mond Procedure(contd.)

3.12. General Screening Analysis

3.13. Sources of Hazard Rating Criteria

3.14. Major Parameters

3.15. Substance Hazard Index (SHI)

3.16. Extraordinarily Hazardous Substance

3.17. Extremely Hazardous Substance

3.18. Extremely Hazardous Substance

3.19. Limit Values and Biological Exposure Indices

3.20. Using IDLH and PEL to Evaluate a Potential Release

3.21. Using IDLH and PEL to Evaluate a Potential Release(contd.)

3.22. HF Based on IDLH

3.23. Using IDLH and PEL to Evaluate a Potential Release(contd.)

3.24. Time to Reach PEL

3.25. Time to Reach PEL

3.1. Screening Analysis Techniques

Over the years, experience with catastrophes in industry has led to a formulation of indices and screening analyses techniques that help determine the risk associated with a particular operation or process. In this section we will describe some of the more important indices used in a risk assessment project.

3.2. Dow Fire and Explosion Index

Purpose: To Realize the Realistic Loss Potential of the Process Under Consideration

Methodology:

Quantify Anticipated Damage

Identify Contributors to Incidents

Communicate The Risk Potential to Management

The Dow Fire and Explosion Index was created by Dow Chemical Company in response to the need to identify areas with major loss potential. It was first published in 1964.

This index divides the plant into manageable sections where the various materials may be identified and analyzed.

The purpose of this index is to have a methodology that can quantify anticipated damage from potential fires and explosions. In addition, any contributors to a potential fire or explosion must be identified. Also, the cost of the potential risk must be conveyed to management.

3.3 Basic Procedures of the Dow Fire and Explosion Index

Select Process

Find Hazard Factor

Calculate Index

Conduct Risk Analysis

Calculate Base MPPD

Audits

Calculate Loss Control Credit Factors

Calculate Actual MPPD

Determine Maximum Probable Days Outage and Business Interruption

The procedure to calculate this index follows the steps listed here. Having selected a process, you must determine the unit hazard factor. This step includes calculations for the general as well as the special process hazards. Next, you must calculate the fire and explosion index which requires finding the exposure radius. This step is followed by a risk analysis which includes calculating a damage factor and an estimation of equipment cost in the exposed area. Next, the maximum probable priority damage (MPPD) must be calculated. Then, the actual MPPD should be found in addition to the maximum number of days of business interruption and the corresponding cos

3.4. Basic Procedures of the Dow Fire and Explosion Index (continued)

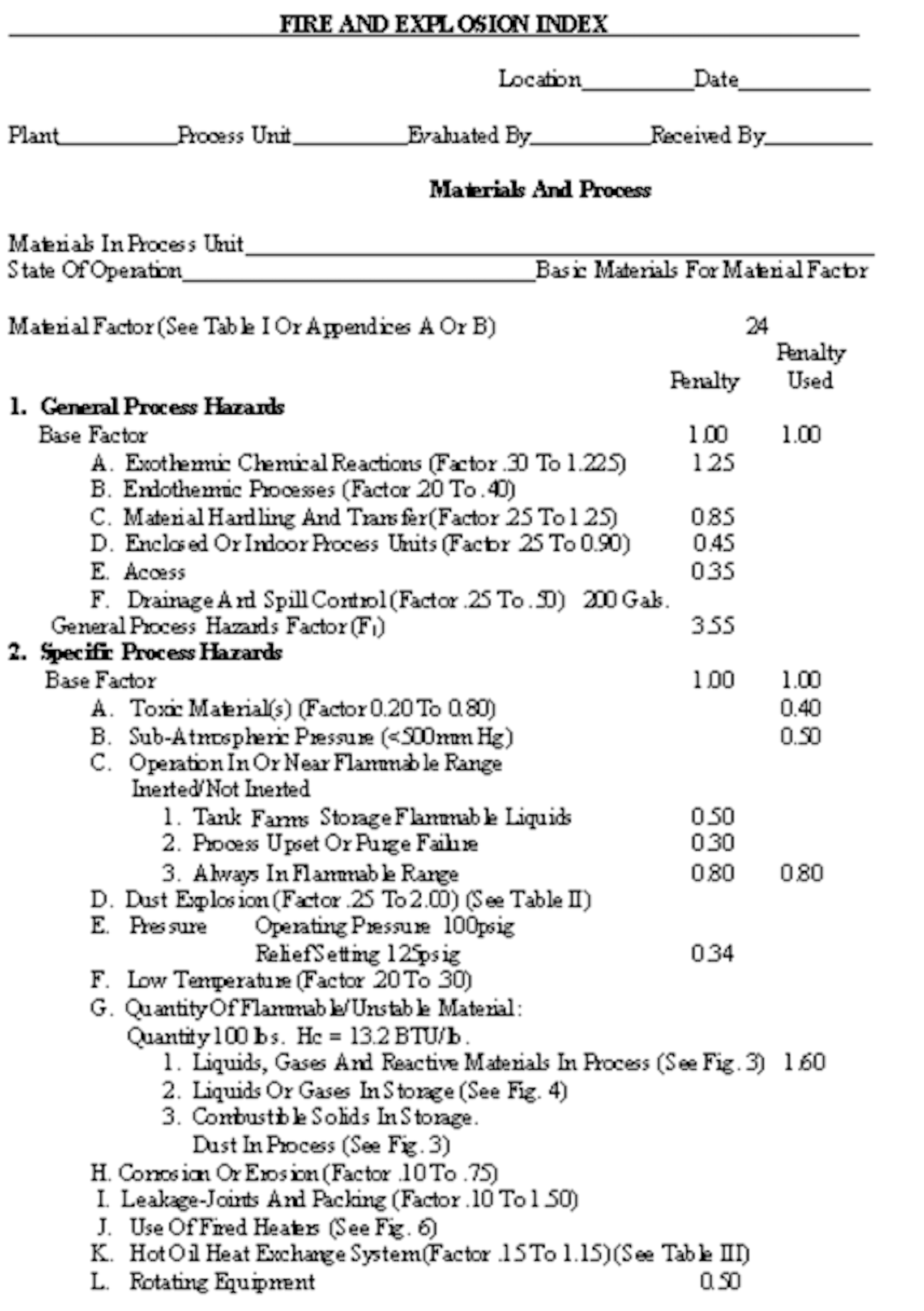

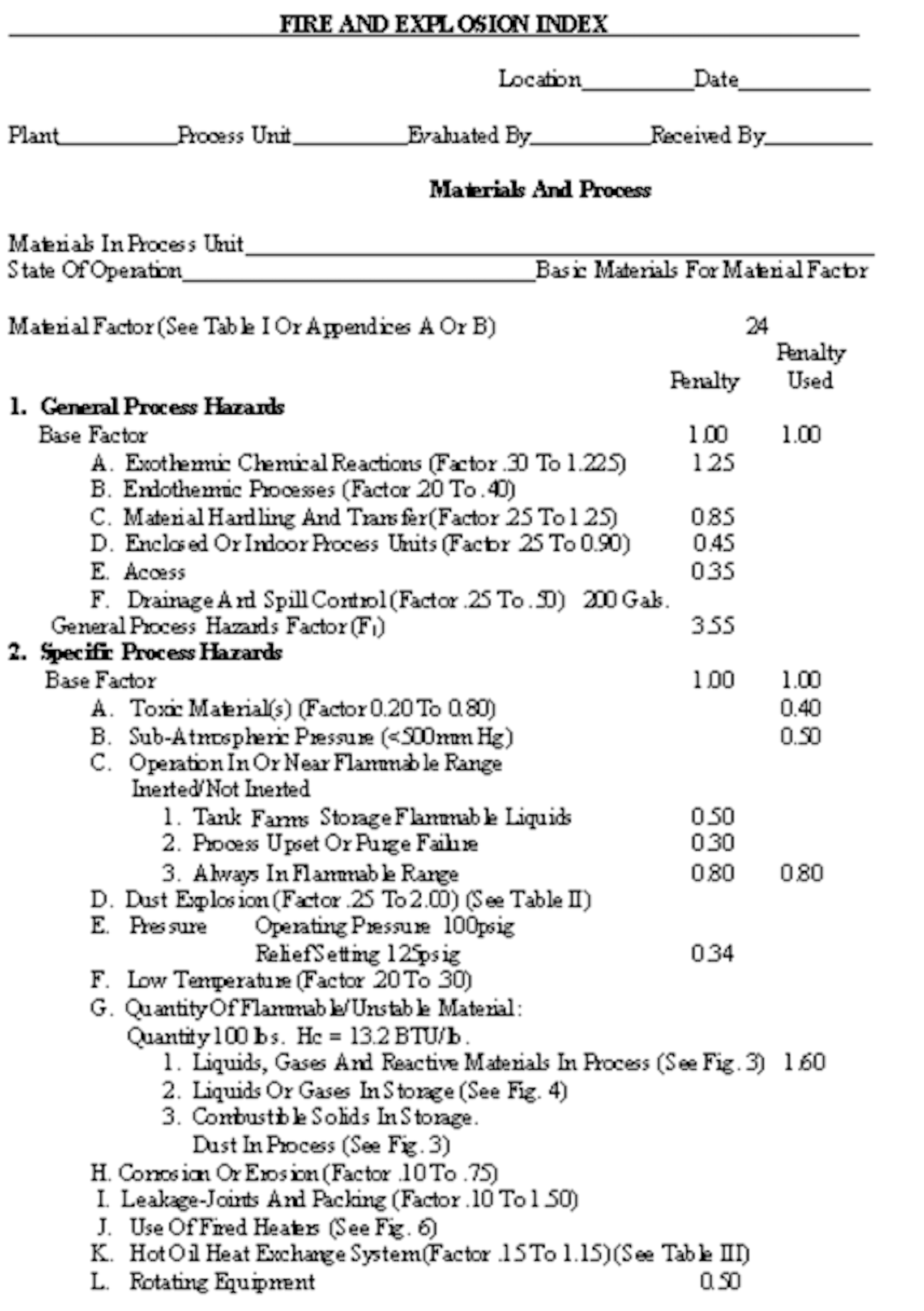

This is an example of the first part of a fire and explosion index form completed for a polyol process from the text by Greenberg and Cramer. Notice the two sections entitled "General Process Hazards" and " Specific Process Hazards". The general process hazards refer to the type of reaction occurring in the process unit. For instance, the more violent the reaction, the larger the penalty, and this means the factor is larger. The second main heading is special process hazards which are factors that contribute mainly to the likelihood that an incident will occur. The headings listed beneath it refer to physical and mechanical properties associated with a process.

3.5. Loss and Control Credit factors

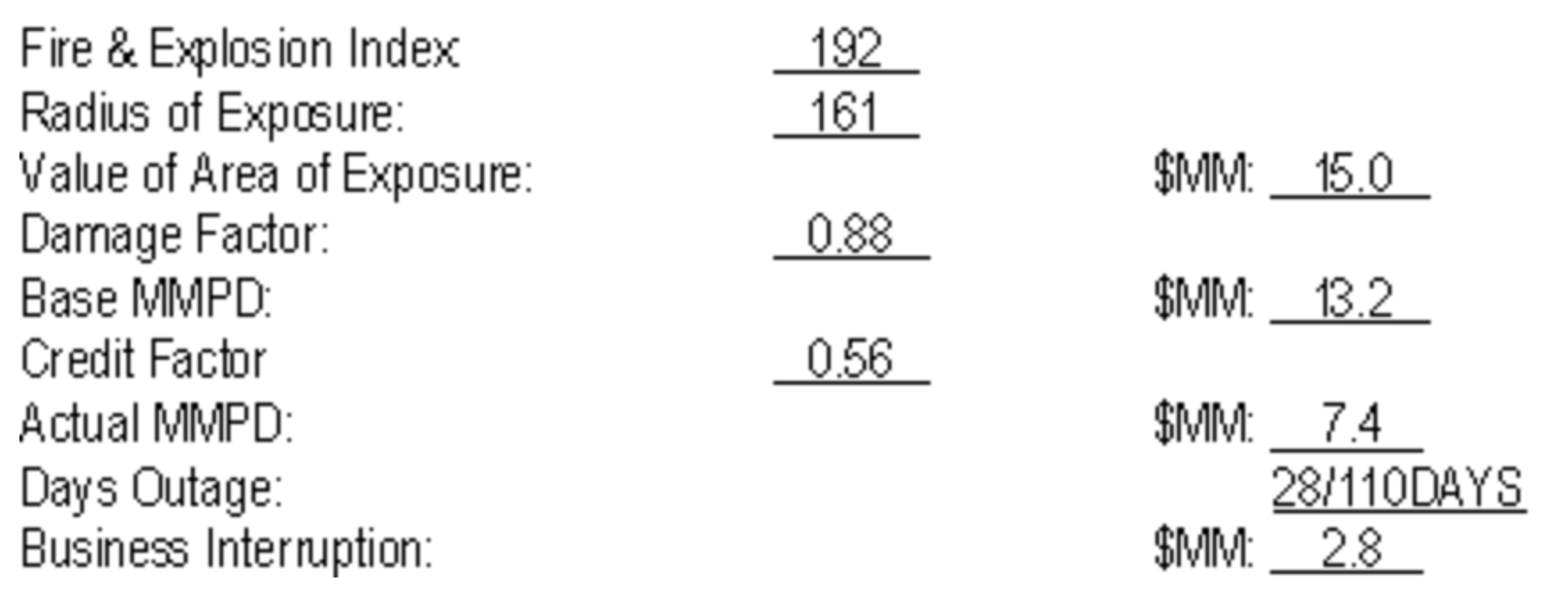

Credit factors are used in calculating the index on this part of the form for the polyol process. These factors are assigned to equipment or procedures that prevent or help deter the effects of fire and explosion. It is a product of three sets of safety systems: level of process control, degree of material isolation and types of protection. All of these are shown on the loss control credit factors data sheet. The credit factor found here is used in the unit analysis summary which is shown on the next slide.

3.6. Unit Analysis Summary

3.7. Mond Fire, Explosion and Toxicity Index

The Mond Fire, Explosion and Toxicity Index is an extension of the Dow Fire and Explosion Index by including toxicity and was developed by the Mond Division of Imperial Chemical Industries. This index is used in the planning stages for a process, and it uses a two part calculation. The initial calculation represents the plant’s worst case hazard. The second calculation corrects the hazard rating.

3.8. Recommendations for Mond Fire, Explosion and Toxicity Index

Place Potentially Hazardous Equipment Away from Vicinity of Personnel

Space Units to Minimize Adverse Effects from Unsafe Incidents

Arrange Plant to Minimize Adverse Effects on Nearby Property

The following recommendations are given by the Mond Index to help reduce risk. These recommendations include locating high risk units near the center of the facility and away from personnel. Use units with a lower risk as buffer. Buildings housing personnel should be located on the perimeter of the plant site.

3.9 Recommendations for Mond Fire, Explosion and Toxicity Index (continued)

Group Small-Potentially Hazardous Equipment Together

Provide Unrestricted Access for Rescue and Firefighters

Additional recommendations from the Mond Index have small potential hazards located together and large potential hazards broken into smaller units to minimize the effects of an explosion or toxic release.

3.10. Mond Procedure

Divide Plant into Units or Processes

For Each Unit Identify:

Hazards of Entering & Exiting Materials

Equipment

Process

Rate Each Component of the Unit

The procedure to perform a Mond Index calculation starts with separating the plant into discrete processes. Then the hazards of the materials entering and leaving the process are identified.

3.11. Mond Procedure (continued)

Review Acceptability of Identified Hazards

Minimize Hazards or Examine Accuracy of Unit Ranking Procedure

Prepare Credits for Overall Risk Factor Reduction

The Mond Index procedure continues as shown above. The initial calculation of the Index is evaluated with no deductions taken for plant fire protection and safety equipment. The second calculation includes all of the plant’s protective equipment. The difference in the Index values implies a level of risk reduction that is attributed to the fire and safety equipment.

3.12. General Screening Analysis

Indices and Databases

Reduce the Amount of Detailed Hazard Analysis by Screening Out Unimportant Chemicals and Processes

In addition to the Dow and Mond Indices, there are a number of other indices and databases used for ranking hazard potentials associated with chemical plants.

These analyses screen out chemicals and processes that do not contribute to the potential risks. This reduces the amount of detailed hazard analysis. In order to determine the risk associated with a particular chemical, each chemical is screened according to their physical and chemical properties. This includes their tendency to react as well as their flammability and toxicity. Fortunately, there exist several databases that organize materials with respect to their hazardous potential.

3.13. Sources of Hazard Rating Criteria

Substance Hazard Index (API RP 750)

Hazardous Chemicals Data (NFC49)

Extremely Hazardous Substance List (EPA 40 CFR 355)

CAMEO Response Information Data Sheets (NOAA)

Limit Values and Biological Exposure Indices

This slide lists some of the important standard indices for hazardous chemicals from industry groups and Federal agencies. The American Petroleum Institute, API, National Fire Protection Association, Environmental Protection Agency and the National Oceanic and Atmospheric Administration.

There are handbooks by Sax and Sittig and EPA databases that have values for these indices. An Internet search is recommended to locate the latest values. These handbooks and databases are constantly updated.

3.14. Major Parameters

Toxicity

Lethal at low concentrations

Readily vaporize into atmosphere

Easily ingested

Flammability

Pyrophoric materials

Liquids with low flash points and ignition points

Capable of exothermic reactions

Reactivity

Strong oxidizers

Capable of detonation

These indices give a measure of the major parameters that must be considered when determining the potential risks of a chemical or process to produce this chemical. A screening analysis includes a review of its toxicity. Toxicity is characterized by its lethality at low concentrations as well as its ability to vaporize into the atmosphere. Also, it includes a review the chemical’s flammability and reactivity. Flammable materials typically include materials that are pyrophoric as well as materials that participate in exothermic reactions. In general, flammable materials are typically liquids with high vapor pressure. Reactive materials are usually strong oxidizers and/or are materials capable of detonation.

3.15. Substance Hazard Index (SHI)

Distinguishes Chemical Substances by their Vapor Pressures and Toxicity Ratings

SHI= EVC/ATCEVC: Equilibrium Vapor Concentration

ATC: Acute Toxicity Concentration

The Substance Hazard Index distinguishes compounds by their vapor pressure and toxicity ratings. A high vapor pressure substance disperses more rapidly into the atmosphere. A highly toxic substance release can pose more danger at low emission rates.

The substance hazard index, SHI, is the ratio of the equilibrium vapor concentration at 20 C, EVC, and the the acute toxic concentration, ATC, as shown on the slide. API Recommended Practices 750 list compounds above 5,000, and arsine has a value of 2,500,000, acrylyl chloride, 164,474 and acrolein 97,807, for example.

3.16. Extraordinarily Hazardous Substance

Name of EHS CAS no Minimum Quantity in Pounds

Hydrogen Chloride 7647-01-0 2,000

Hydrochloric Acid 36% by weight HCl 7647-01-0 5,600

Allyl Chloride 107-05-1 2,000

Hydrogen Cyanide 74-90-8 500

Hydrogen Fluoride (HF) 7664-84-1 500

Hydrofluoric Acid >70% by wt 7644[84-1] 39-3 700

Chlorine 7782-50-5 500

Phosphorous trichloride 7719-12-2 500

Hydrogen Sulfide 7783-06-4 500

Phosgene 75-44-5 100

Bromine 7726-95-6 100

Methyl isocyanate 624-83-9 100

Toluene-2-4-diisocyanate 584-84-9 100

The New Jersey Toxic Catastrophe Prevention Act identified several chemical substances that can cause acute health effects and possible death if released into the air. These substances have been deemed: Extraordinarily Hazardous Substance otherwise known as (EHS). These substances, if released into the environment, would result in death or permanent disability to those exposed.

3.17. Extremely Hazardous Substance

List Published by EPA

Substances That Can Cause Serious Irreversible Health Effects from Accidental Releases

Another list of substances known as the Extremely Hazardous Substance was published by the EPA under the

Emergency Planning and Community Right–to–Know Act.

3.18. Extremely Hazardous Substance

Some EPA Extremely Hazardous Substances from Greenberg and Cramer

Cas no. Chemical Name Threshold Reportable Quantity Planning Quantity

75-89-5 Acetone Cyanohydrin 10 1000

1752-30-3 Acetone 1 1000/10000

107-02-8 Acrolein 1 500

79-06-1 Acrylamide 5,000 1000/10000

107-13-1 Acrylonitrile 100 10000

814-68-6 Acrytyl Chloride 1 100

111-69-3 Adiponitrile 1 1000

116-06-3 Aldicarb 1 100/10000

309-00-2 Aldrin 1 500/10000

107-18-6 Allyl Alcohol 100 1000

107-11-9 Allylamine 1 500

20859-73-8 Aluminum Phosphide 100 500

54-62-6 Aminopterin 1 500/10000

78-53-5 Amiton 1 500

3734-97-2 Amiton Oxalate 1 100/10000

7664-41-7 Ammonia 100 500

16919-58-7 Ammonium 1 10000

300-62-9 Amphetamine 1 1000

62-53-3 Aniline 5,000 1000

88-05-1 Aniline, 2,4,6-Trimethyl 1 500

7783-70-2 Antimony Pentafluoride 1 500

1397-94-0 Antimycin A 1 1000/10000

86-88-4 ANTU 100 500/10000

1303-28-2 Arsenic Pentoxide 5,000 100/10000

1327-53-3 Arsenous Oxide 5,000 100/10000

7784-34-1 Arsenous Trichloride 5,000 500

7784-42-1 Arsine 1 100

2642-71-9 Azinphos-Ethyl 1 100/10000

The characteristics that constitute an extremely hazardous substance include toxicity, physical form, and how the chemical is used. This is a list of substances considered to be extremely hazardous.

3.19. Limit Values and Biological Exposure Indices

IDLH = Immediate danger to Life & Health

IDLH concentration has adverse effects on life and health for an exposure time of 30 minutes

PEL = Permissible Exposure Limit

PEL is the time weighted concentration which should have no adverse effect on an average worker

These indices are two of several that are used to determine toxicity and characterize health risk at locations in a facility. These values for a chemical can be found in databases and on Material Safety Data Sheets (MSDS).

3.20. Using IDLH and PEL to Evaluate a Potential Release

Hydrogen fluoride, HF, is very toxic

It is used in a 18x24x9 ft lab

If a container of HF is released into the room, what is the max amount that can be kept in the room, and still not pose an immediate danger to the lab staff?

Hydrogen fluoride is a very toxic substance and is normally stored and used in well-vented chemical hoods. A worst-case scenario is posed that a container containing HF is brought to a laboratory to be placed in the hood. During the transfer, a valve fails, and HF is released. We need to determine the maximum amount that can be kept in the room and not cause an immediate danger to the laboratory staff. The following slide provides data for this evaluation.

3.21. Using IDLH and PEL to Evaluate a Potential Release

IDLH level for HF = 20 ppm

PEL = 3 ppm

MW HF = 20.01

Boiling Point @ 1 atm = 67 deg. F

Using this data evaluate the maximum amount of HF that could be kept in the room if it was suddenly released and still not pose an immediate danger to the laboratory staff.

Compare your result with the calculation given on the next slide.

3.22. HF Based on IDLH

Safe amount to have in the lab:

The lab volume is needed since the HF will rapidly disperse throughout the room.

Calculate the volume of the lab:

V = (18)(24)(9) = 3888 ft3

Calculate the moles of air present:

Use the ideal gas law to calculate the total number of moles of air in the lab at ambient conditions, 1.0 atmosphere and 70 oF (530oR).

N = (PV)/(RT) = (1.0)(3888)/(0.7302*530) = 10.05 lb moles

Calculate the “safe” amount of HF:

The “safe” amount in this case would correspond to the IDLH level. At this level, workers would have adequate time to leave the room. The IDLH is given in units of ppm, i.e., parts-per-million by volume. The answer is readily converted to lbs and grams.

A = (IDLH)(N) = (0.000020) (10.05) = 0.000201 lb moles = 0.00402 lb = 1.82 grams

To evaluate the amount of HF that could be present in the laboratory based on the Immediate Danger to Life and Health index, the volume of the laboratory is calculated. Then the number of moles of air is determined using the ideal gas law. Then using the value of 0.000020 (20 ppm) for the IDHL index the amount of HF is 1.82 grams.

3.23. Using IDLH and PEL to Evaluate a Potential Release

Laboratory ventilation system mixes the air thoroughly

Air is changed every ten minutes

Determine the time required to purge a sudden release of 150 grams of HF before the laboratory was safe to use.

The laboratory ventilation system mixes the air thoroughly and provides one change of air every ten minutes.

Determine how long would it take to purge a sudden release of 150 grams of HF to reach the permissible exposure limit (PEL) of 3 ppm.

Compare your results with the calculations given on the next two slides. Approximate the room as being a completely mixed vessel with a residence time of 10 minutes.

3.24. Time to Reach PEL

Time to purge lab from release of 150 grams of HF:

The lab can be considered a large, stirred tank with a residence time of 10 minutes. The differential equation describing the concentration of a substance initially present at

V(dC/dt) = -FC where V = tank volume and F = fluid flow rate

The solution to this equation is: C = CO e-Ft/V

which can be arranged to: t = -(V/F) ln (C/CO)

Concentration CO in such a tank is:

Calculate the initial concentration of HF in the lab. Convert 150 grams to lbs., then to lb. moles.

Amount of HF = 150 grams = 0.330 lb = 0.0165 moles

The room is approximated as a large, stirred vessel with a uniform concentration throughout. With no flow of HF into the room, the equation that describes the decay in concentration with time is given by the derivation shown on the slide. This equation can be expressed as the time to reach a given concentration. The initial concentration in the room is calculated as shown on the next slide.

3.25. Time to Reach PEL

Divide the number of lb moles of air present to get the mole fraction of HF. Multiply by 1,000,000 to get ppm.

CO = (0.0165/10.05) = 0.00164 mole fraction = 1640 ppm

Calculate the air flow rate. The room has a change of air every ten minutes.

F = (3888)/(10) = 388.8 ft3/min

Calculate the time needed to reach the PEL concentration. Use the equation given above.

t = -(V/F) ln (C/CO) = -(3888/388.8) ln (3/1640) = 63 minutes

The initial concentration is the moles of HF divided by the sum of the moles of air and HF in the room. Then the flow rate of air into and from the room is evaluated as shown.

The information is now available to evaluate the time required for the concentration of HF in the room to decrease to 3 ppm.

This calculation uses the approximation that the air in the room is perfectly mixed. Some space in parts of the room can be incompletely mixed, in the corners for example. Consequently, it would be advisable to wait three to four times as long before entering the room, and the air should be sampled following procedures for entering confined vessels.