Chapter 9. Hazard and Operability Studies (HAZOP)

9.1. Hazard and Operability Studies (HAZOP)

9.2. Hazard

9.3. Operability

9.4. HAZOP

9.5. Study Action Report

9.6. Typical Preparatory Steps

9.7. Typical Preparatory Steps(contd.)

9.8. HAZOP Agenda

9.9. HAZOP Agenda(contd.)

9.10. Plant Walk - Through

9.11. Risk Matrix

9.12. Definitions and Recommended Actions

9.13. Interim Report

9.14. Final HAZOP Report

9.15. Final HAZOP Report(contd.)

9.16. HAZOP Illustration

9.17. HAZOP Illustration(contd.)

9.18. HAZOP Illustration(contd.)

9.19. HAZOP Illustration(contd.)

9.20. HAZOP Illustration(contd.)

9.21. HAZOP Illustration(contd.)

9.22. HAZOP Illustration(contd.)

9.1. Hazard and Operability Studies (HAZOP)

HAZOP is a simple yet structured methodology for hazard identification. It allows the user to employ imaginative thinking in the identification of hazards and operational problems. It is a systematic and methodical examination of design documents that describe a plant. It is performed by a multidisciplinary team to identify hazards or operability problems that could result in an accident.

9.2. Hazard

Anything that can lead to an unwanted event

9.3. Operability

Anything that causes an operator to improvise in his or her actions

A hazard is defined as anything that can lead to an unwanted event. This slide lists some examples of hazards in industry including a runaway chemical reaction, an equipment malfunction, and an operator error.

9.4. HAZOP

A HAZOP study is performed by a multidisciplinary team. This team identifies hazards of operability problems that could result in hazards. It studies deviations from the design using guide words to control the evaluation. It provides a vehicle for recommendations for plant design or procedural modifications. Also, it provides safety documentation and is a basis for a risk management program.

9.5. Study Action Report

9.6. Typical Preparatory Steps

There are many preparatory steps that should be made before executing a HAZOP. These steps include: verifying P&IDs, setting line segment boundaries and compiling a list of support documents. Supporting documents often include: P&IDs, PFDs, process description, operating manuals/procedures, processing materials information, and equipment and material specification. Tentative scheduling is also conducted which allots time to be spent per P&ID sheet. Also, the method of recording is selected. This is done manually using a data sheet or more frequently with a computer program.

Additional preparatory steps are given on the next slide.

9.7. Typical Preparatory Steps(contd.)

List standard abbreviations and acronyms compiled

Devise critical rankings

Give HAZOP training to all team members

Arrange for process/system briefings before begin wor

9.8. HAZOP Agenda

Introduce team members

Present HAZOP methodology

Discuss AHM properties

Identify hazards, goal, and scope of HAZOPClassify risk matrix parameters

Define AHM release scenarios

Give detailed process description

The HAZOP agenda is listed here. A short resume is included for each team member. The HAZOP methodology is presented by the team leader. Then, an industrial hygienist describes the AHM (acutely hazardous materials). The other agenda items are covered and a plant walk-through is held to obtain an overview of the facility as shown on the next slide.

9.9. HAZOP Agenda (continued)

Prepare computer program to record proceedings

Conduct plant walk-through

Hold team meetings to review facilities

Prepare interim report for management

Prepare a formal report of results

At team meetings a systematic segment-by-segment review of the facility is made. The interim report serves to notify plant management of any critical hazards that might have been identified. The formal report is a permanent record of the team’s meetings and findings. There are guidelines for these reports.

9.10. Plant Walk - ThroughProvides an overview audit of plant facilities

Provides a general feeling for the condition of the unit

Helps team in assessing hazard criticality and probability

The plant walk-through is one of the steps taken early in the HAZOP study. The walk-through provides a view of the scope and condition of the plant which is used in their assessment of criticality and probability.

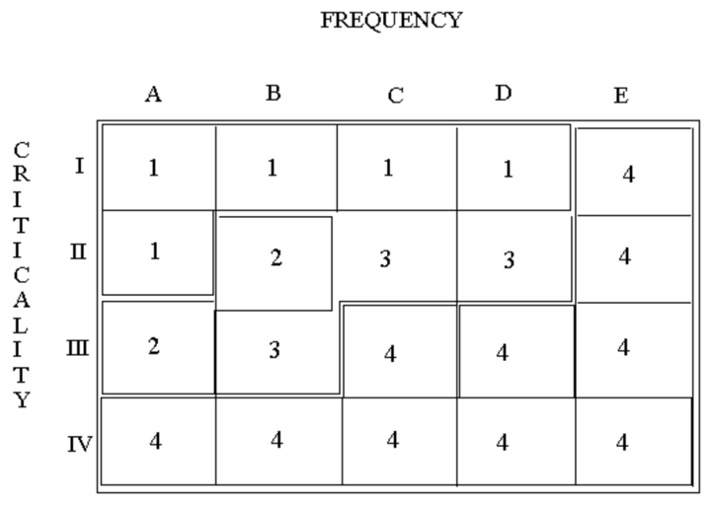

9.11. Risk Matrix

Criticality must be assigned to the identified hazards. After hazards are ranked on the basis of level of criticality and frequency, a risk matrix is often prepared. This matrix gives further ranking of hazards based on acceptability. This matrix provides a simple priority sorting method. The rankings are then given definitions and recommended actions. The meaning of these numerical rankings from one to four are shown on the next slide.

9.12. Definitions and Recommended Actions

Ranking Description Required Mitigation

1 Unacceptable Should be mitigated with engineering or administrative controls to a risk ranking of 3 or less

within a specified time period such as 12 months.

2 Undesirable Should be mitigated with engineering or administrative controls to a risk ranking of 3 or less

within a specified time period such as 12 months.

3 Acceptable with controls Should be verified that procedures controls are in place.

4 Acceptable as is No mitigation action required.

This slide shows a table of definitions and recommended actions for rankings. The ranking numbers are the ones shown in the Risk Matrix table on the previous slide. Note that for a ranking of 1, the hazard is deemed undesirable and should be mitigated with engineering or administrative controls to a risk ranking of 3 or less within a certain time period, for example six months.

9.13. Interim Report

HAZOP identification

List of team members

List of reference documentation

List of preliminary identified hazards

Basis of risk matrix

List of base study documents reviewed

The interim report includes the items shown on this slide. In developing this report, if the HAZOP team finds a hazard that poses an immediate danger, the team presents these findings verbally to plant management to expedite any required mitigation.

9.14. Final HAZOP Report

Purpose and scope defined

Key members present

Documentation used

Preliminary hazard identification

Criticality evaluation

The final effort of the team is a report that serves as a permanent record of their activities and findings. It contains the information listed in this slide and the next slide.

9.15. Final HAZOP Report (continued)

Procedures addressed

AHM, MSDS addressed

Spill size quantified & evaluated

Instrumentation addressed

Thorough cause investigation

It must contain all of the documentation to show the necessary steps were followed, and demonstrate the HAZOP was performed properly. It will be key documentation in an audit by Federal agencies as required by law.

9.16. HAZOP Illustration

For each section of a plant, the team reviews:

Intention: How the process is suppose to operate?

Deviations: Guide words used to suggest other ways the process might operate

Causes: Is it realistic that these deviations could occur and how?

Consequences: Result if deviation occurs

Hazards: Consequence result in a hazardous situation

A HAZOP analysis will be illustrated by considering the knock-out vessel system described in the section on operation procedures. A team consisting of a process engineer, chemist, plant operator, maintenance supervisor and safety engineer have been assembled. They are to proceed through the steps shown on this slide. They will use guide words shown on the next slide to evaluate deviations.

9.17. HAZOP Illustration (continued)

Guide words to evaluate deviations:

No or Not : The intended operation does not take place

More or Less: The intended process takes place but to a greater or lesser degree than intended.

As well as: Something else takes place as well as the intended process

Reverse: The opposite of the intended operation takes place

Other than: Something entirely different from the intended process takes place.

These are the guide words used by the team to perform the HAZOP analysis. These guide words are applied in the following slides on the knock-out vessel.

9.18. HAZOP Illustration (continued)

The flare header collects inert gases and light hydrocarbon vapors from several locations. The knock-out vessel is suppose to collect any liquids that might condense in the flare line. Estimates indicate between 10 and 500 lb per hr of liquid will reach the vessel.

A process flow diagram and process description is the minimum information required and this is given in the slide. For this section of the plant, a flare header collects inert gases and light hydrocarbon vapors from several locations around the plant. The knock-out vessel is supposed to collect any liquids that might condense in the flare line and have only gas and vapors going to the flare. Estimates indicate between 10 and 500 lb per hr of liquid will reach the knock-out vessel.

The next slides give the intentions, deviations cause consequences and hazards developed in the HAZOP analysis.

9.19. HAZOP Illustration (continued)

Intention:

The knock-out vessel is designed to collect liquid hydrocarbons from the flare header and divert it to waste liquid recovery instead of having it burned in the flare.

Deviations:

1. No: No liquid comes to the vessel.

2. More or less: More than 500 lb/hr, or less than 10 lb/hr, of liquid comes to the vessel.

3. As well as: Liquid water enters the vessel along with hydrocarbons.

4. Part of: Does not apply.

5. Reverse: Liquids flow from the vessel back into the flare header.

6. Other than: The liquids do not separate in the vessel but go on out to the flare.

The intention of the knock-out vessel is designed to collect liquid hydrocarbons from the flare header and divert it to waste liquid recovery instead of having it burned in the flare. The guide words are used to evaluate the deviations. The application of the guide words are shown on the slide. These deviations are used in development of the list of causes shown on the next slide.

9.20. HAZOP Illustration (continued)

Causes:

1. A. No hydrocarbons heavy enough to condense are flowing in the flare header.

B. Flare header is blocked.

2. A. [More] Plant upset is venting more than expected amounts of condensable hydrocarbons.

B. [More] Liquids are leaking into flare header from some source in the plant.

C. [Less] Same as 1.A. and 1.B., above.

3. A. Water is leaking into flare header system.

B. Air with high moisture content is leaking into plant and into flare system.

C. Water is present in light hydrocarbons.

5. A. Check valve is installed backwards.

B. Block in line to flare causes pressure buildup in vessel.

6. A. Too much turbulence in vessel.

B. Vessel residence time is too short.

C. Vessel is full of liquid due to faulty level control.

D. Vessel is full of liquid due to blocked liquid exit line.

This slide lists the causes from using the guide words.

The guide word NO led to the causes that hydrocarbons heavy enough to condense are flowing in the flare header and the flare is.

When the guide words MORE and LESS were uses, MORE led to the causes that a plant upset is venting more than expected amounts of condensable hydrocarbons and more liquids are leaking into flare header from some source in the plant. When LESS was used causes were the same as when the guide word no was used.

When the guide words AS WELL AS were used, the cause was that water is leaking into flare header system, air with high moisture content is leaking into plant and into flare system and water is present in light hydrocarbons.

The guide word PART OF does not apply.

The guide word REVERSE led to the cause that the check valve is installed backwards and a block in line to flare causes pressure buildup in vessel.

The guide word OTHER THAN led to causes that there was too much turbulence in vessel, the residence time is too short, the vessel is full of liquid due to faulty level control and the vessel if full of liquid due to blocked liquid exit line.

9.21. HAZOP Illustration (continued)

Consequences:

1. A. Vessel could dry out, possible divergence of vapors to liquid waste recovery unit.

1. B. Could result in unsafe conditions upstream in plant.

2.A. and 2.B. May be too much flow for liquid waste recovery unit.

3.A., 3.B. and 3.C. No major problem if liquid unit can handle water.

5.A. and 5.B. Flare won’t operate. Major safety problem.

6.A. and 6.B. Carryover of small amount of liquid to flare; no significant problem.

6.C. and 6.D. Carryover of large amount of liquid to flare; flare capacity could be exceeded.

This slide lists the consequences from the causes listed on the previous slide. Consequences from NO LIQUID coming to the vessel includes the vessel could dry out, possible divergence of vapors to liquid waste recovery unit and could result in unsafe conditions upstream in plant.

Consequences from MORE than 500 lb/hr or less than 10 lb/hr may be much flow for liquid waste recovery unit.

Consequences from liquid water AS WELL AS hydrocarbons entering the vessel could be no major problem if liquid unit can process water.

Consequences for liquid REVERSE flow is that the flare would not operate, a major safety problem.

Consequences from OTHER THAN where liquids do not separate but go out the flare are carryover of small amount of liquid to flare, no significant problem. However, if there is carryover of large amount of liquid to flare, flare capacity could be exceeded.

9.22. HAZOP Illustration (continued)

Major hazards:

Corrective action needed:

1.B., 5.A., 5.B., 6.C., and 6.D.

Moderate hazards:

Corrective action needed:

1.A., 2.A., and 2.B.

No hazard:

3.A., 3.B., 3.C., 6.A. and 6.B.

The HAZOP analysis identified the major hazards shown this slide. They include 1.B if the flare header is blocked, it could cause unsafe conditions in the plant. Also, if the check valve is installed backwards or the line is blocked to the flare, the flare will not operate. In addition, if the vessel is full of liquid due to faulty level control or a blocked exit line, there could be a carry-over of a large amount of liquid and the flare’s capacity would be exceeded.

Moderate hazards requiring corrective actions are identified, also, as are cases that are not hazards, as shown on the slide.